Large submerged arc welding machine

Submerged arc automatic welding machine, can be used for carbon steel, low alloy steel, high strength steel parts butt welding, mainly for Φ≥ 300mm circumferential seam welding. This machine has two kinds of power supply characteristics of thick wire and thin wire. The diameter of the welding wire applied by the filament special machine is Φ1.6~Φ2.0, which can achieve lower heat input. Fully welded ball valve body-When the connection body is welded, there are rubber sealing parts near the weld. When the insulating joint flange-fixing sleeve is welded, there are also rubber sealing parts near the weld. In order to prevent rubber parts from scalding during welding, the welding temperature must be controlled, so the low heat input wire submerged arc welding process has significant advantages. Coarse silk special

Key words:

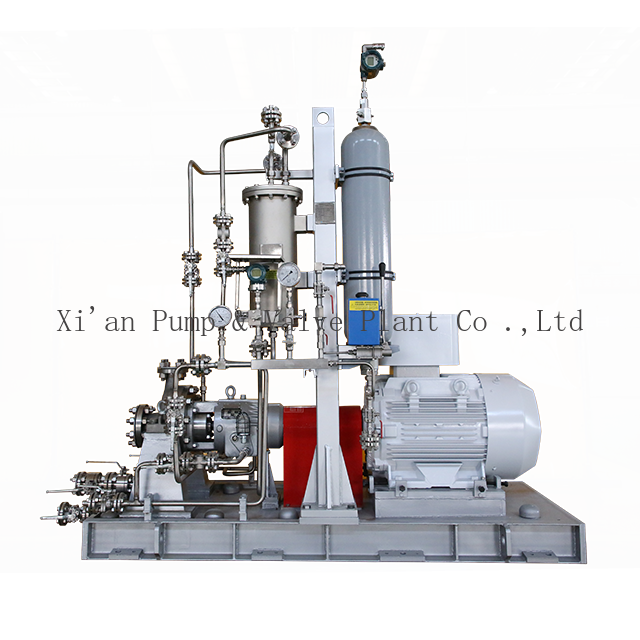

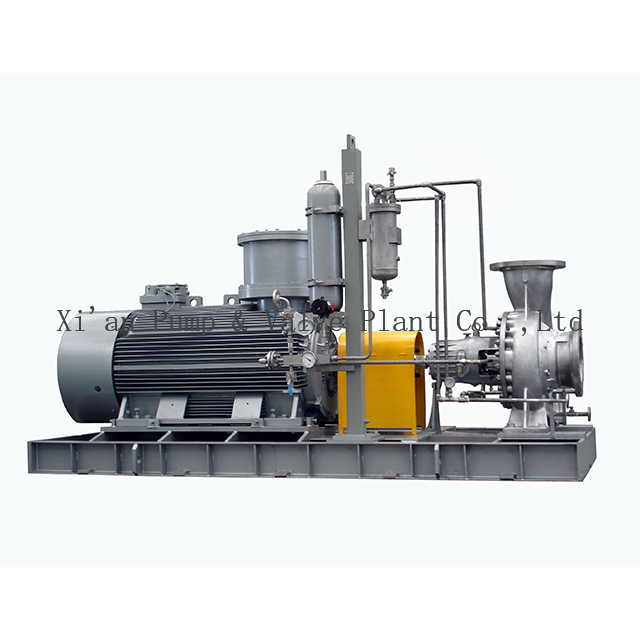

Key words:Zirconium,Pump

Classification:

Product Description

Product inquiry

Note: Please leave your mobile phone and email address, our professionals will contact you as soon as possible!