Advantages of casting

After unremitting efforts, Xi’an Pump & Valve Plant Co.,Ltd has now become a professional pump and valve manufacturer integrating R & D, design, manufacturing, sales and pump and valve maintenance. It is a key backbone enterprise and comprehensive solution provider in the domestic pump and valve industry.

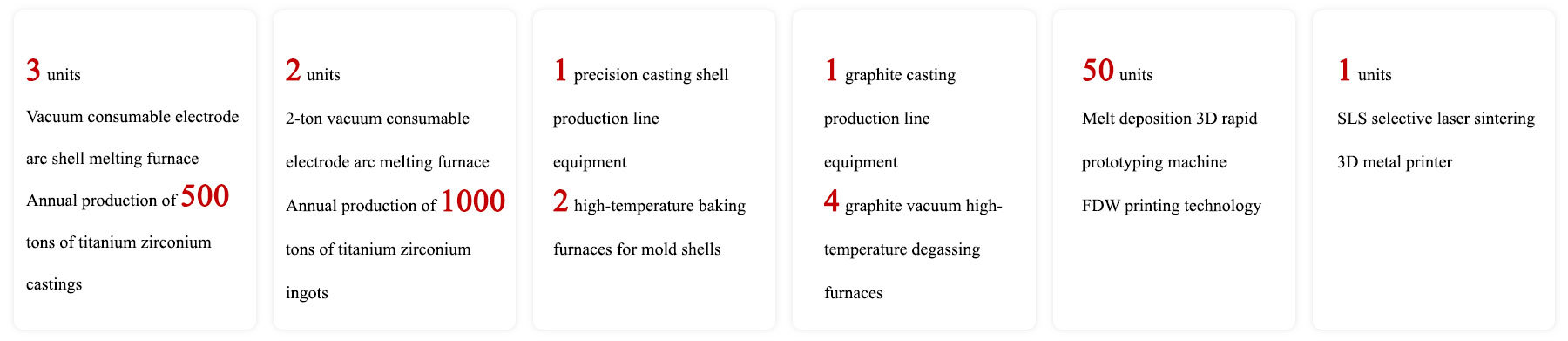

Our unit has two 2T vacuum consumable electrode arc melting furnaces, with an annual output of 500T of various titanium zirconium ingots. It has one graphite mold production line and one precision casting mold shell production line. For graphite mold production line, it has two graphite CNC machining centers and four graphite vacuum high-temperature degasser furnaces, which are used to produce large pump valves and other castings. It has one investment precision casting model production line and two mold shell high-temperature baking furnaces, it is used to produce castings with complex structure and high dimensional accuracy. Especially for the mold shell precision casting production line, it has one selective laser sintering 3D rapid prototyping machine (SLS printing technology) and three fused deposition 3D rapid prototyping machines (FDW printing technology), which are used for precision casting rapid molding and shorten the development and production cycle. It has 3 vacuum consumable electrode arc shell melting furnaces (1 set of 1000KG and 2 sets of 500KG), with an annual output of 350 tons/year of various special material castings. It can produce TA2, TA9, TA10, TC4, TB32 and other titanium and alloy castings conforming to GB/T 6614, and can produce Zr-3, Zr-5 and other zirconium and zirconium alloy castings conforming to YS/T 853, titanium and titanium alloy castings such as Grade C- 2, Grade C- 3, Grade C- 5, Grade C- 7 and Grade C- 12 conforming to ASTM B367 can be produced, and zirconium and zirconium alloy castings such as 702C and 705C conforming to ASTM B7532.